Machine main configuration and construction

1, Work area tunnel outer body: high quality 304 yarn surface stainless steel

2, Work area tunnel cavity: mirror stainless steel Model: #304

3, Body support frame: Fangtong Steel set Model: 2′′ Fangtong

4, Air transport system: one set of forced air combination blower (extracting harmful gas) Model: 6 inch

5, Insulation material: vacuum aluminum silicate + silk double layer Model: 60K

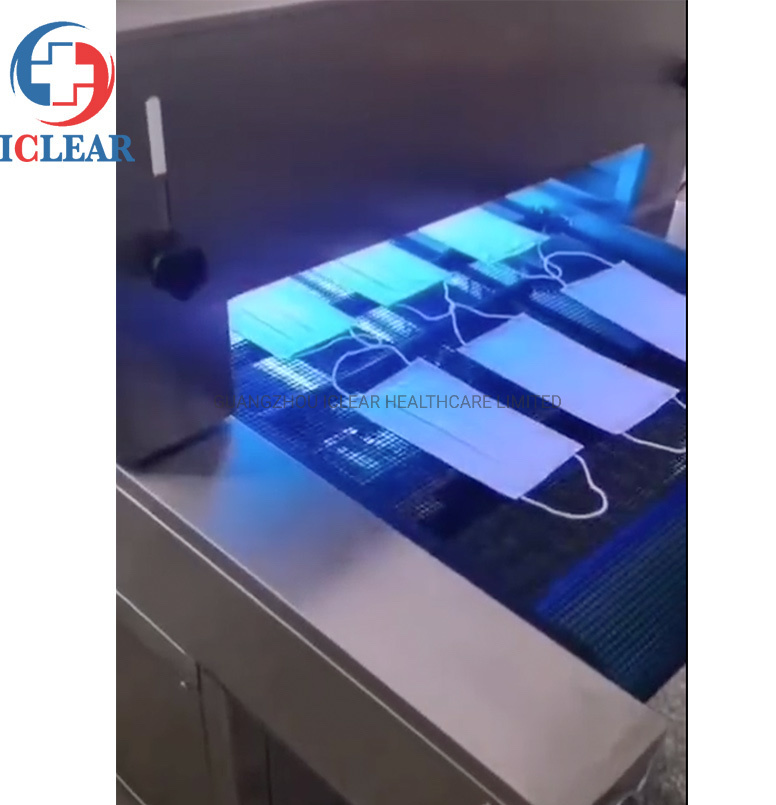

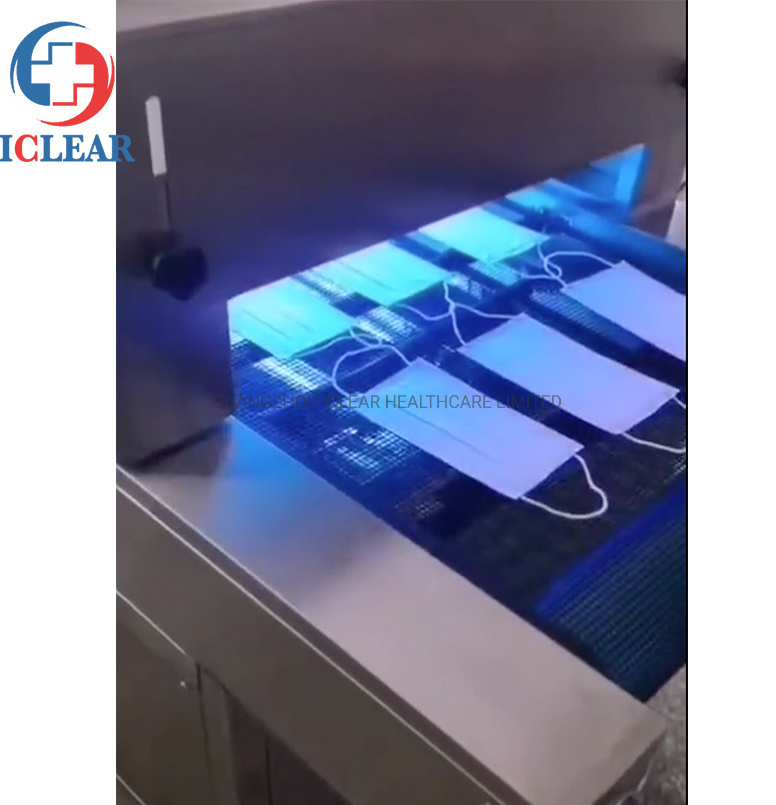

6, Conveyor belt: Teflon mesh belt 1. Main switch: 20A

7, Transport motor: 800W (inverter speed regulation)

8, Governor: 50W (electronic step-less frequency converter speed digital display speed operation)

9, Exhaust fan: CY-125

10, Ammeter: 50A set

11, Voltmeter: 220V set

12, Working voltage:20V (±10) three-wire system 50Hz

13, UV light source effective light moment: 150mm

14, Lamp length: 600mm

15, UV ultraviolet germicidal lamp 16 * 20W UV lamp in the longitudinal direction of the lumen, upper, lower, left and right installation wavelength 253.7nm, 1-meter distance intensity is 160 microwatts / square centimeter or more. The service life is more than 8000 hours.

Power supply equipment and precautions

1, Power supply: AC220V 1.3KW 50Hz

Voltage allowable range: ±5% of the rated value

(The range that can be operated is ±10%)

2, Maximum current: 50A

3, When placing the cabinet, be careful that the distance to the wall should be greater than 100 mm.

safety equipment

Temperature overheat preventer (protecting the test object and test chamber)

Fault alarm prompt

Overvoltage and overcurrent protection

Equipment overload protection